April 9, 2023 – Are you a manager or owner of a Canadian building with a gearless 2:1 Turnbull-Dover (purchased circa 2000 by now TK Elevator)? If so, listen up.

It’s not always fun to unpack the technical jargon of gearless and 2:1 if you don’t speak elevator, so we’re going to make it easier to understand. Let’s start with the risk.

It’s not always fun to unpack the technical jargon of gearless and 2:1 if you don’t speak elevator, so we’re going to make it easier to understand. Let’s start with the risk.

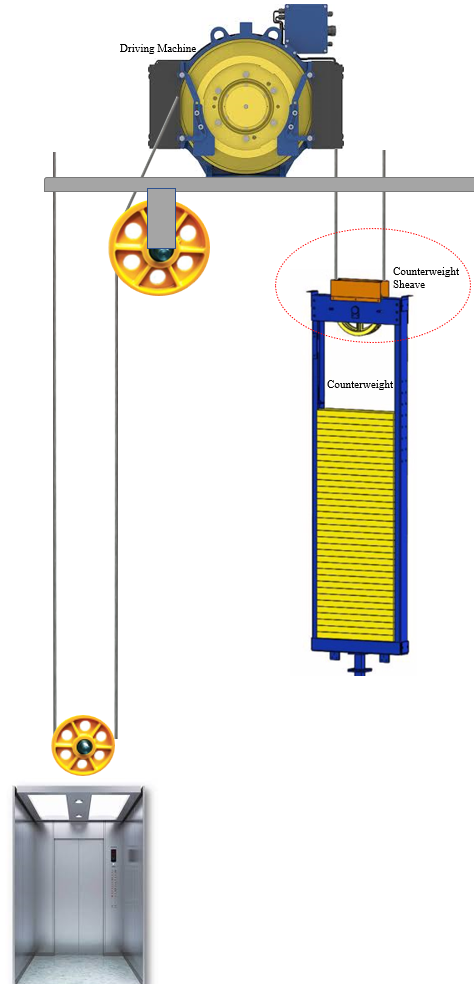

There have been incidents related to 2:1 gearless Dover Elevators where the counterweights (pictured) have separated from their respective ropes and were either hanging by a thread, or the counterweight sheave (pictured, circled in red) separated from the frame and fell into an elevator cab.

What is a counterweight? A counterweight is the counterbalance that is attached to the other side of the cab which allows us to balance the elevator system. This counterbalance permits us to use less power to move the cab in the up and down direction.

The problem with the system is related to the idler sheave (steel wheel) on top of the counterweight, which is sealed and cannot be lubricated. When the bearing is worn it becomes seized, tearing into the structure holding the sheave in place. This initiates the tearing and separation of the brackets holding the sheave in place. In one instance, this caused the releasing of the ropes, which allowed the counterweight to fall into the pit (photo #3), and the cab to then free fall. In this instance, the sheave could also fall out of the frame into the shaft and if the cab is below the counterweight, the sheave could crash into the cab (photo #2).

There is a good description of this danger in a bulletin produced by TK Elevator and can be seen here: https://novascotia.ca/lae/equipmentsafety/docs/manufacturer-safety-bulletin-2023-01-03-tke.pdf.

Luckily, we have not seen any fatalities thus far. However, we’re aware of some unsettling information. In one instance where a counterweight idler sheave crashed into an elevator, it fell only 30 minutes after the noise of the malfunction was detected by the building.

Why is this extremely concerning? From when the building operator became aware of the problem to when the counterweight idler sheave fell into the elevator, there was not enough time for the elevator contractor to attend to the site and fix the problem. Ideally for non-emergency response, we want the elevator company to attend the site within two hours. In this case, within 30 minutes, the catastrophic failure occurred.

What can be done to combat this serious issue? Clients in Canada (this is not applicable to the US clients) who work with Solucore and with this type of elevator equipment have been sent an email notification by our team. We keep a database of the equipment we inspect and are able to identify possible problem sites. For owners of Turnbull-Dover equipment that do not work with us, we recommend contacting your elevator contractor to determine if you own this equipment. Please note that many Turnbull-Dover Elevators have been modernized by various elevator companies and you may have different controllers, but the counterweights are usually retained. You may have one elevator company's controls, with a different company’s counterweights. It’s important that you know who the original equipment manufacturer was, more than what elevator controls you currently have.

Diligence in inspecting the bearings of these sheaves and immediately shutting down an elevator making unusual noise is of the utmost importance. Time is of the essence.

Solucore is aware that the Technical Standard and Safety Authority (TSSA) is reviewing this issue and will likely issue a Director’s Order to repair this unsafe situation, which is not covered under a maintenance contract. Those needing to update should budget roughly $20,000 per elevator, and a one-week shutdown to perform the repairs.

If you have any questions, please feel free to contact us at (905) 206-0555 or find your local branch here so that we can assist you. Please be diligent in this important matter.

Photo #1 - Bearing Shaft

Photo #2 - Counterweight Idler Sheave

Photo #3 - Counterweight in the pit