Introduction

On Friday, January 27, 2006 five people riding an elevator were injured at 522 University Avenue, National Life building. We understand from news reports and bulletins that the hydraulic shuttle elevator fell five stories and crashed into the pit. While there can be many causes for hydraulic elevator crashes, we believe that this incident should raise awareness on single bottom cylinders.

Hydraulic Elevators Type

Hydraulic oil elevators use cylinders to go up and down. The cylinder is driven by hydraulic fluid hence the name. There are numerous configurations to hydraulic elevators like: 1. Direct acting (buried in the ground); 2. Holeless (installed above ground); 3. Roped hydraulic (above ground cylinder which uses ropes as well); and 4. semiholeless (partially buried). For our purpose of awareness, we will discuss direct acting elevators because they are the type equipped with single bottom cylinder.

Hydraulic Cylinders

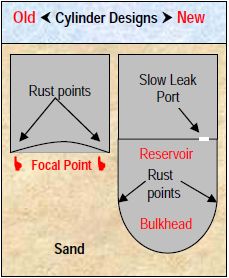

The construction of hydraulic cylinders consisted of single bottom design and more recently double bulkhead. The advantage of double bulkhead design versus single is in the construction of a control down valve. The double bulkhead was similar to the old design, but had the added security of a hole in the cylinder located at the bottom wall ``Slow Leak Port''. If the cylinder integrity is good, then the hole was encapsulated ``Reservoir Bulkhead'' and did not allow the oil to escape, however, if the bottom cap rusted and deteriorated, then the oil would escape from the ``Slow Leak Port'' to the environment in a controlled and consistent fashion, hence allowing maintenance personnel to notice the problem and remove the elevator from service. Therefore, if you have cylinders with double bulkhead, you can rely on good preventative maintenance and diligence to retain the elevator cylinder in the ground or you can plan to replace it proactively within 50 years of installation.

Single Bottom Cylinders

Most cylinders manufactured prior to the 1970's were of the single bottom design. This design is more susceptible to rust because the cylindrical design with flat bottom area does allow for concentration of underground currents to a focal point shown in red. The electrolytic action damages this weld more rapidly then other parts of the cylinder. Since we cannot inspect the condition of the buried cylinder, it is difficult to assess the life of single bottom cylinders. While some have lasted over 50 years others failed after only 12 years. This time span can decrease or increase significantly given soil acidity level and water table condition. Furthermore, buried cylinders are covered in protective coating which consists of rust inhibiting paint; tar based protective coating or both. If the cylinder's protective coating was damaged during the installation, this can effectively reduce the life of the cylinder even more. One thing for sure though, given the pressure in the system, some catastrophic failures have occurred with little to no warning causing fatality. Therefore, where single bottom cylinders are concerned, we recommend immediate replacement of the cylinders.

Cathodic Protection

In the 1970's and 1980's there was a push for cathodic protection to prevent the cylinders from failing. This system works by turning the cylinder into a cathode and more easily corroding metal as the anode like magnesium. The magnesium would then corrode but the cylinder will not. The magnesium can be replaced by an inert or iron anode if a continuous external power source is used to hold the iron anode at a magnesium potential. Hence the problem with this system: elevator contractors did not maintain the power source nor did they report its failure to the building Owners and hence numerous cathodic protection system were left unattended and became ineffective. In some cases, the cathodic protection accelerated the deterioration of the cylinders in instances where the cylinders were touching earth or exposed to it in one spot.

What Can You Do?

First thing to do is identify the type of hydraulic cylinder you have in the building. Your elevator contractor can be a great resource in acquiring this information and assessing the risk. If the cylinder is a single bottom design, then you should act.

Option 1 - Replace the cylinder. This option is a longterm option that can provide you with peace of mind and can also improve the value of your asset. Single bottom cylinders are usually identified during a building condition audit and the replacement value is usually deducted.

Option 2 - Retain the cylinder, but install a safety clamp. This is a good option only in cases where the cost to replace a cylinder is prohibitive or in the event that removing the elevator from service for three or four weeks is out of the question. The disadvantage of this option is the limitation of the product (cannot be installed on all hydraulic elevators) and you still have to replace the cylinder at some point.

|

Options & Costs |

2 - 3 floors |

4 - 6 floors |

| Option 1 - Replace Cylinder | $35,000 $45,000 | $55,000 - $65,000 |

| Option 2 - Cylinder Clamp | $12,000 $13,000 | $14,000 $15,000 |

|

Options & Schedule |

2 - 3 floors |

4 - 6 floors |

| Option 1 - Replace Cylinder | 2 Weeks - 3 Weeks | 3 Weeks - 5 Weeks |

| Option 2 - Cylinder Clamp | 1 Week - 2 Weeks | 2 Weeks - 3 Weeks |

In the Province of Ontario, the elevating devices act requires from elevator contractors to maintain an oil logbook in the machine room of each hydraulic elevator. The purpose of the logbook is to keep track of oil losses and to monitor changes in oil levels. Through our site inspections, we have noted that some contractors are not diligent in maintaining accurate oil logbooks. We have noted for example oily pits which should indicate that there was oil loss to the concrete from a bad packing or coupling. Yet, the oil loss is not documented at all. While there is no need for action by the contractor to remove the elevator from service in the event that oil loss in accounted for, there is a genuine need for contractors to report the oil loss so that adding oil can also be noted. As properly managers, you can easily visit the machine room and inspect the logbook. Discouraging signs to look for include:

In the Province of Ontario, the elevating devices act requires from elevator contractors to maintain an oil logbook in the machine room of each hydraulic elevator. The purpose of the logbook is to keep track of oil losses and to monitor changes in oil levels. Through our site inspections, we have noted that some contractors are not diligent in maintaining accurate oil logbooks. We have noted for example oily pits which should indicate that there was oil loss to the concrete from a bad packing or coupling. Yet, the oil loss is not documented at all. While there is no need for action by the contractor to remove the elevator from service in the event that oil loss in accounted for, there is a genuine need for contractors to report the oil loss so that adding oil can also be noted. As properly managers, you can easily visit the machine room and inspect the logbook. Discouraging signs to look for include:

As you can see from the photo above, we observed significant quantity of oil in an elevator pit. While it would not have been possible for the Owners to observe this oil in the pit, the scent of oil was present.

Published in Published in Canadian Property Management Magazine March 2006